For assistance in your next project contact one of our offices to discuss more.

Radiographic Examination of Metals

i. Welded Joints

ii. Castings

Penetrant Testing (fluorescent & Visible)

i. Water Washable Method

ii. Solvent Removable Method

Magnetic Particle Testing (fluorescent & Visible)

i. Magnetic Flow Method

ii. Current Flow Method

Welding Qualification Examining Body Inspections required to verify compliance with the process for qualifying welders for fusion welding of steels in accordance with AS/NZS 2980

Welder qualifications in accordance with specifications such as:

Ultrasonic Examination of Metals

i. Wrought Products

ii. Welded Joints

iii. Castings

iv. Forgings

Ultrasonic Examination of Components & Assemblies

i. Bonded assemblies such as bearings for bond failure

ii. Thickness measurements

Manual Phased Array

(ii) Welded joints Al, Fe, SS

Non Destructive Tests by Eddy Current Testing (Al, Cu, Fe, Ni, Mg, Zn)

(a) Surface flaw detection

(b) Metallic coating thickness measurement

(c) Sorting of materials & Components

(d) Sub surface flaw detection

(e) Weld Testing

Visual Inspection of metals

(i) Welded Joints

Ferrous Metals (incl. Stainless Steels)

(ii) Castings

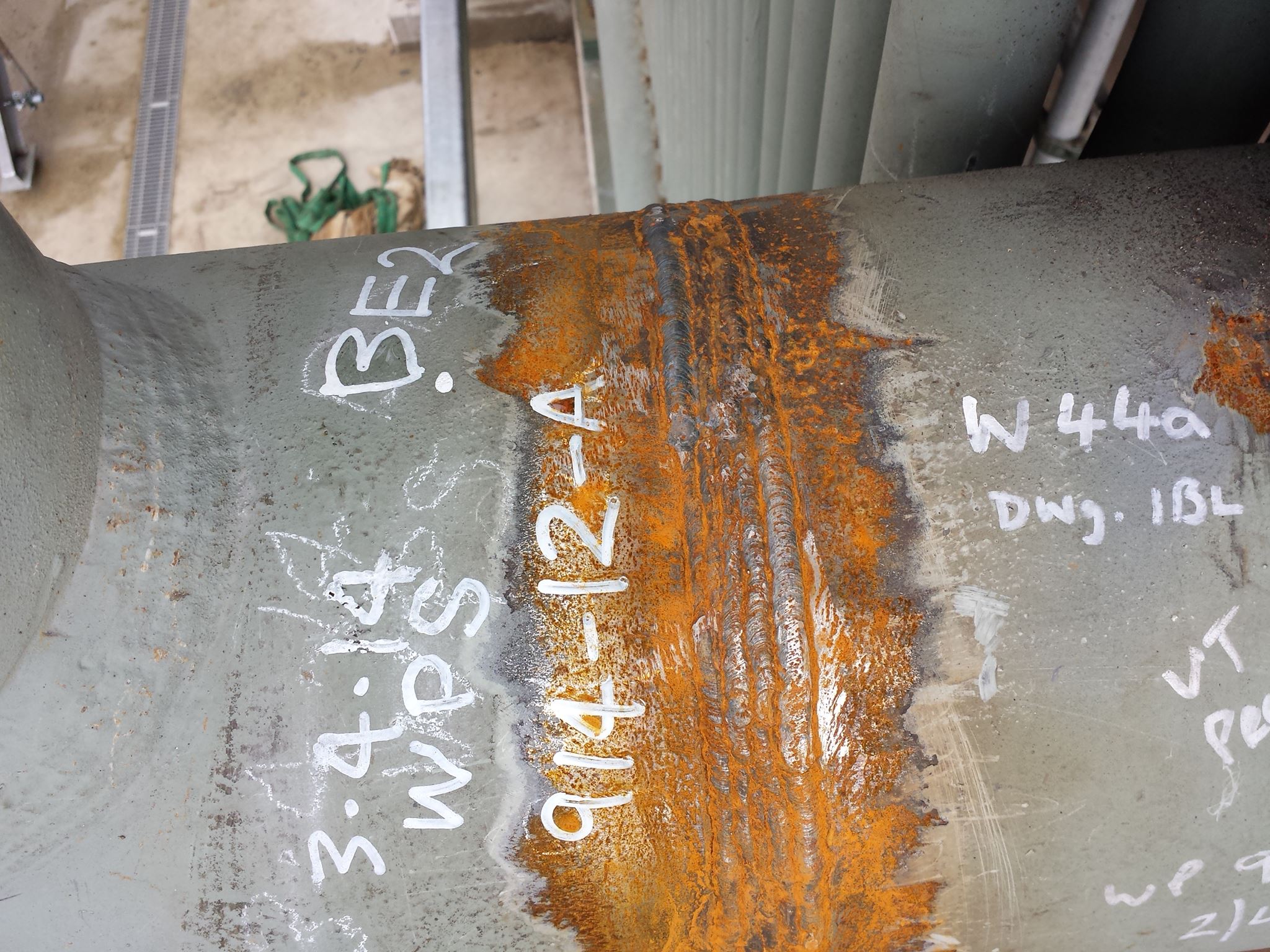

Weld inspection on new boiler for Oceania Dairies at Glenavy

If you would like to find out more about our services, or you have an opportunity for Design Engineering to assist with your engineering service requirements on any given project, and/or require a free quotation, please contact us

Te Rapa, Hamilton | P. +64 7 850-1177

Christchurch | P. +64 3 348-6713

Timaru (Head Office) | P. +64 3 688-6713

Dunedin | P. +64 3 477-1713